Machine tools

Annet GRAULE QNF Crosscut saw with TigerStop TS 4.8 L Au

5 041EUR

- ≈ 5 918 USD

- ≈ 4 393 GBP

Handpress

Fotpress Munktells TA1

Wise Service Logistic composition of business residues WS700

32 950EUR

- ≈ 38 686 USD

- ≈ 28 717 GBP

Wise Service Saw for cutting the remote frame WS1080

10 100EUR

- ≈ 11 858 USD

- ≈ 8 802 GBP

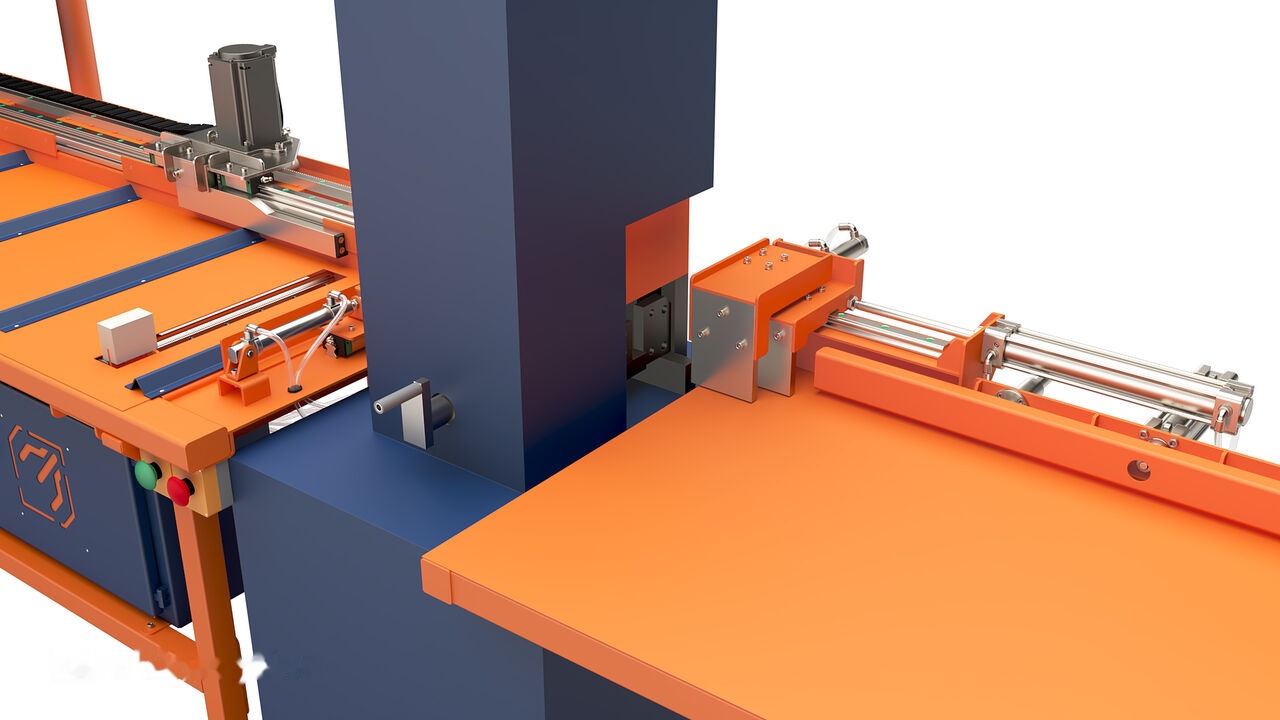

Wise Service Automatic positioner for installing the corresponding bars WS301

7 150EUR

- ≈ 8 394 USD

- ≈ 6 231 GBP

Wise Service Double-headed station for drilling holes for the impost in the frame WS402

19 450EUR

- ≈ 22 836 USD

- ≈ 16 951 GBP

Wise Service Measuring automatic roller conveyor WSR3000

6 200EUR

- ≈ 7 279 USD

- ≈ 5 403 GBP

Wise Service Automatic guillotine for cutting metal WS7050

25 900EUR

- ≈ 30 408 USD

- ≈ 22 573 GBP

Wise Service Roller conveyor with automatic positioning WSR3010

3 700EUR

- ≈ 4 344 USD

- ≈ 3 224 GBP

Wise Service Automatic single-headed guillotine for cutting WS G1

6 350EUR

- ≈ 7 455 USD

- ≈ 5 534 GBP

Wise Service Center for automatic milling of aluminum profiles WS710

19 800EUR

- ≈ 23 246 USD

- ≈ 17 256 GBP

Wise Service Automatic machine for bending aluminum profile WS790

28 400EUR

- ≈ 33 344 USD

- ≈ 24 752 GBP

Hydroscand H24D

3 258EUR

- ≈ 3 825 USD

- ≈ 2 839 GBP

HH Stenenknipper

80EUR

- ≈ 93 USD

- ≈ 69 GBP

Bandzaag G 5013 W

250EUR

- ≈ 293 USD

- ≈ 217 GBP

ABC Cyklop Axro 3k

Spielvogel 346 – Bridge saw / Brückensäge

Machine Tools for Sale

Machine tools are an essential part of any manufacturing or industrial operation. They are devices used to shape or machine metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformation. Applications of machine tools include creating individual parts, large-scale production, and anything in between.

Types

There are a variety of machine tools available. The most common types include:

- Metalworking machinery – spin the workpiece against a cutting tool

- Milling machines – use a rotating cutting tool to remove material

- Grinding machines– use an abrasive wheel to shape the workpiece

- Drill presses – ideal for accurate drilling in various materials

- Saws – including band saws and circular saws for cutting tasks

- Planers – used to create flat surfaces with high precision

Each type of machine tool is designed for a specific manufacturing process.

Key Technical Specifications

When selecting machine tools, it's crucial to consider their technical specifications. These may include the tool's power source (electric, hydraulic, pneumatic, etc.), operational speed, material compatibility, size and weight, and the precision and accuracy of the tool.

Popular Brands and Models

Popular brands of machine tools include:

- Haas – known for its CNC machines, such as the Haas ST and VF series

- Mazak – recognized for multi-tasking machines like the Integrex series

- Doosan – offers versatile CNC lathes and machining centers

- DMG Mori – famous for high-precision and automated machines

Each brand offers various models with different features and capabilities.

Prices and Availability

The price of machine tools can vary greatly depending on the brand, model, and whether the tool is new or used. New machine tools tend to be more expensive but come with warranties and the latest features. On the other hand, used or second-hand machine tools are often more affordable and are a good choice for businesses on a budget.

For example, a used Haas CNC lathe may cost around €25,000–€40,000, while a new one can reach €80,000–€100,000. A Mazak vertical machining center might range from €30,000 used to over €100,000 new. Basic drill presses and grinders can be found starting from €500 to €5,000 depending on condition and features.

Buy Machine Tools on Truck1

If you're looking to buy machine tools, consider using the Truck1 platform. Here, you can find a wide range of new and used machine tools from various brands. You can easily compare prices and specifications to find the best fit for your needs — or use the I'm looking for feature to submit a custom request.

FAQ

When buying used machine tools, you should consider the tool's condition, age, brand, and any maintenance records. You should also ensure the tool has no significant damage and is in good working order.

Common maintenance issues with machine tools include wear and tear on moving parts, alignment problems, and issues with the power source or control system.

To ensure compatibility, you should check the power requirements, size, and operational specifications of the machine tool against your existing factory equipment.

Prices for Machine tools

| Wise Service Logistic composition of business residues WS700 | 32 950 EUR | |

| Samoa Ghibli | 405 EUR | |

| Samoa Sirio 45:1 | 1 215 EUR | |

| ABC Unknown | 148 EUR | |

| Microstep MG 12001.42GGprB | 26 991 EUR | |

| Euromair JetPro 100 | 2 159 EUR | |

| Wise Service Automatic screwing center WS910 | 22 450 EUR | |

| VEM IE2-W21R 250M 6LL HW | 1 350 EUR | |

| ..Select Make IE3-W43R | 2 699 EUR | |

| Wise Service Automatic roller conveyor with resetter WSR7001 | 11 400 EUR |