Metalworking machinery

BURGSMUELLER VIWM 800_CNC

KORRADI VH1000-CNC

Stähleschleifmaschine REMA

Schwenkbiegemaschine FASTI

Radien-Abrichtapparat JUNG

CNC-Fräsmaschine MIKRON

Abkantmaschine KRAMER AM-aut II 2000/2,25

CNC-Fräsmaschine BOLLA LUX

Planscheibe

1 Satz nach außen abgestufte Backen

Abwickelhaspel WÖLLNER

Vierbackenfutter KLOPFER

Profilstahlschere IMS

Mehrspindelbohr- u. Gewindeschneidkopf

Koordinatenmarkier- u. Zentrierbohrmaschine BÖNI

Universalfräsmaschine HERMLE

Prisma-Unterwerkzeug

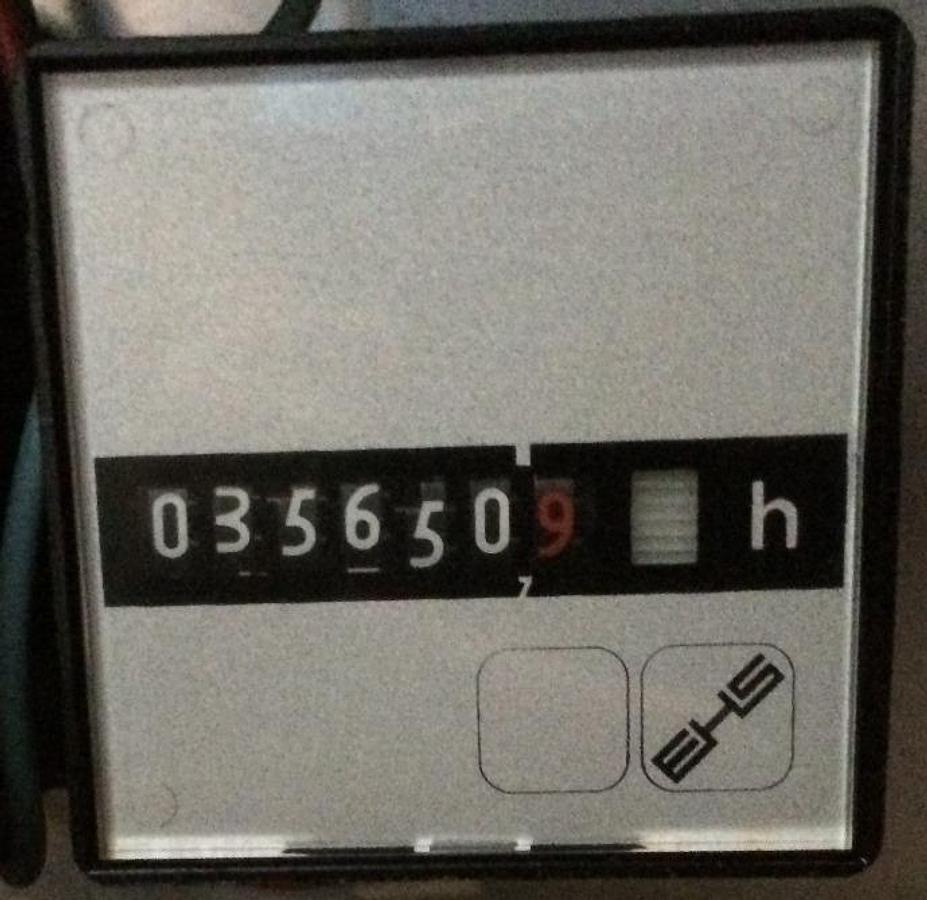

CNC-Abkantpresse EHT

Tafelschere WEINBRENNER

Dreiwalzen-Rundbiegemaschine

Teilapparat CARL ZEISS

Leit- u. Zugspindeldrehmaschine VDF-HEIDENREICH & HARBECK

Metalworking Machinery for Sale

Metalworking machinery is a broad term that includes a wide range of tools and equipment used to cut, shape, and assemble metals into finished products. These machines are essential in various industries such as automotive, aerospace, construction, and many more where metal components and structures are required.

Types of Metalworking Machinery

There are several types of metalworking machinery, each designed for specific tasks. Some common types include:

- Milling machines – used for precision cutting and shaping of metal surfaces

- Lathes – ideal for rotating and cutting cylindrical parts

- Grinders – used to achieve smooth and accurate finishes

- Press brakes – for bending metal sheets into precise angles

- Welding machines – for joining metal parts together using various welding techniques

Key Technical Specifications

When choosing metalworking machinery, some critical specifications to consider are power capacity, size of worktable, maximum cutting, grinding or bending capacity, spindle speed, and accuracy level.

Popular Brands and Models

Some of the leading brands in metalworking machinery include:

- Haas – known for its high-performance milling machines and CNC systems

- Amada – excels in press brakes and laser cutting systems

- DMG Mori – offers a broad range of lathes and milling machines with automation options

- Trumpf – renowned for its advanced laser technology and sheet metal machinery

Prices and Availability

Prices for metalworking machinery can vary greatly, depending on whether you're buying new or used, the brand, model, and its condition. New machinery often comes with the latest technology and warranty but at a higher cost. Used metalworking machinery, on the other hand, can offer significant savings, particularly for small businesses or startups.

For example, a used Amada press brake might cost around €20,000–€35,000, while a new model could exceed €70,000. CNC lathes from DMG Mori or Haas typically range from €25,000 used to over €100,000 new. Basic grinders and welding units can start from €1,000 to €10,000 depending on features and wear.

Buy Metalworking Machinery on Truck1

Truck1 is a reliable platform to buy both new and used metalworking machinery. With a wide variety of brands and models available, you can find the right equipment to suit your needs and budget. Not sure what exactly you're looking for? Try using the I'm looking for feature to submit your request to sellers.

FAQ

When buying used metalworking machinery, consider factors such as the machine's overall condition, its service history, the availability of spare parts, and the reputation of the brand and seller.

The lifespan of metalworking equipment can vary greatly, depending on the type of machine, frequency of use, and maintenance practices. However, many machines can last for decades with proper care and maintenance.

CNC (Computer Numerical Control) machines are most suitable for high-precision tasks. These machines use computer programs to control the cutting and shaping processes, ensuring high accuracy and consistency.

Prices for Metalworking machinery

| Onbekend | 170 EUR | |

| Ercolina MB42-PT-1 | 590 EUR | |

| Dirinler CDCS 800 P | 1 000 EUR | |

| Selco Genesis 2200 AC-DC EasyArc | 290 EUR | |

| Walmag BM 3600 | 250 EUR | |

| SIEGMUND | 290 EUR | |

| SIEGMUND | 650 EUR | |

| SIEGMUND | 750 EUR | |

| Onbekend | 100 EUR | |

| Gaussian | 270 EUR |