Transmission

Sennebogen 850 C series Linde swing gear l

Sennebogen 850 C series Linde swing gear l

Sennebogen ZF DR250 053017 and ZF DR350 250184 slewing gear

Terex AC 205 Planetary gear 17-24-67-32-3pl-H136-46

Terex AC 155 Planetary gear 17-24-67-32-3pl-H136-46

Krupp KMK 5100 Mid differential 13x35 axle 2

Krupp 70 GMT End differential 17x36 axle 1

Kessler planetary gear 21-21-63-40-4pl-H140-46

Grove AT 633 planetary gear 22-25-74-38-4pl-H137-46

FAUN HK 40 planetary gear 27-18-65-24-4pl-H64-24

Gottwald mid differential 14x34 axle 4

Kessler Mid differential 17x36

Grove AT 633 end differential 13x35 axle 2

Kessler planetary gear 22-25-74-40-4pl-H177-46

Kessler+Co Kessler End differential 18x35

Liebherr LTM 1160-2 Mid differential 13x35

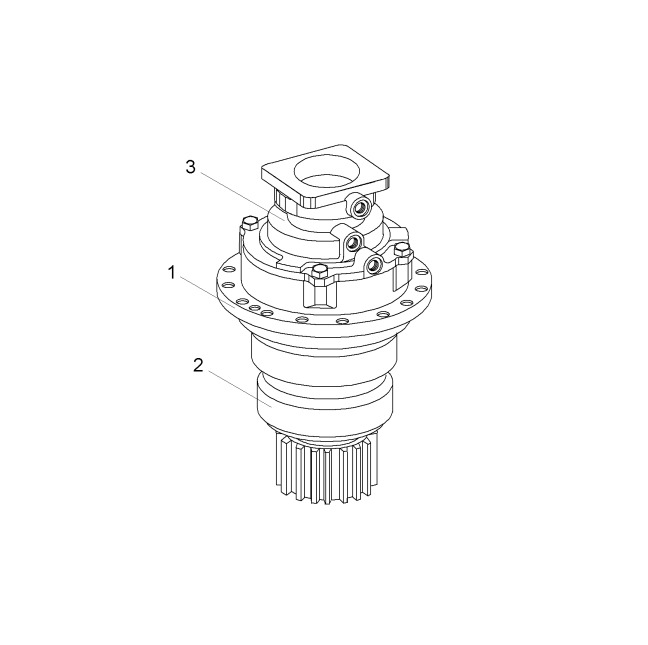

Grove GMK 5150 multiple-disk brake slewing gear

Krupp 70 GMT end differential 17x36 axle 4

Atlas Terex Linde GS 2500 aus 1905 M

Liebherr SAT 225 aus LH A902LIT

Atlas Linde HMV 70 / 1704

900EUR

- ≈ 1 027 USD

- ≈ 778 GBP

The ability of the internal combustion engine to adapt to external load changes compared to the reciprocating steam engine or electric series motor is small. This circumstance led to the installation of gearboxes, providing the necessary traction to drive wheels in different modes of motion. Due to the presence of gearboxes vehicles can move at low and maximum speed. It allows you to adjust the speed within a much larger range than the one that can be provided by an engine. It also should be mentioned that gearboxes allow vehicles to move backwards, and they also disconnect the engine from the drive wheels when starting, stationary or coasting.

They try to develop gearboxes for trucks so that they guarantee the necessary dynamic and economic properties for the vehicle, and also work quietly, with a high efficiency, being reliable, easy to service, possibly having a small size and weight, and low cost.

In recent years, manufacturers of trucks have been increasingly focused on making the process of shifting automatic. On trucks operating in the city, it dramatically improves the driver's working conditions and, accordingly, a positive effect on traffic safety. On the main transport automation gear also improves the efficiency of transport, since it allows optimizing the interaction between engines and gearboxes. As a compromise, cheaper than the automatic gearboxes, all the more common are becoming semi-automatic, as a rule, no torque converter. They relieve the driver of one of the most energy-intensive operations associated with the gear shift, either by squeezing the clutch pedal, or from the actual switch, which is transferred to a switch by a joystick. There have already appeared constructions, for example, Volvo I-Shift, working as a full automatic with torque converter. It should be noted that in all three cases, the basic box is mechanical.

The vast majority of manual gearboxes are performed with the undivided power flow, so that all the power flow goes through each switched gear wheel. The use of such schemes is due to the desire to increase the life of gearboxes at high transmit power.

On the trucks the most widely used three-shaft boxes with direct transmission, which is obtained by connecting the primary and secondary shafts.