Asphalt plants leasing

22

See all Construction machinery for sale

30

See all photos (20)

Electric

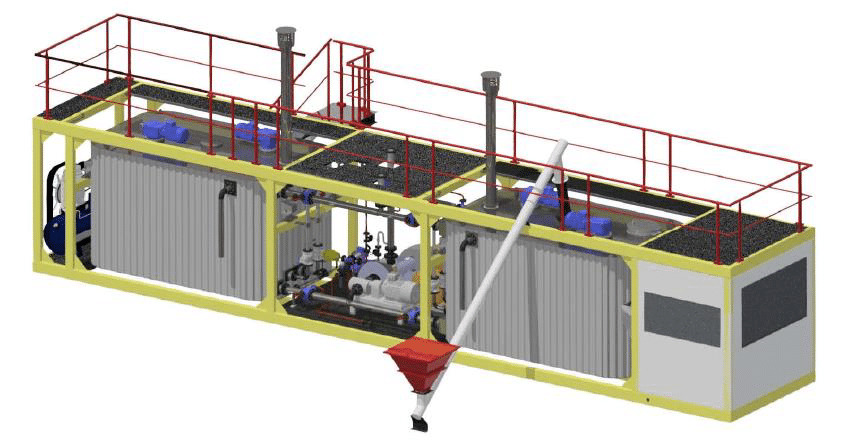

Stainmann COLDMIX asphalt plant

Asphalt plant

2021

Lithuania, Kirtimu street 17A, Vilnius

Published: 4d

120 000EUR

Price excl. VAT

Auction

- ≈ 139 122 USD

- ≈ 104 752 GBP

2021

Lithuania, Kirtimu street 17A, Vilnius

Contact the seller

See all photos (20)

Asphalt production line asphalt plant

Asphalt plant

Lithuania, Kirtimu street 17A, Vilnius

Published: 4d

52 800EUR

Price excl. VAT

Auction

- ≈ 61 213 USD

- ≈ 46 091 GBP

Lithuania, Kirtimu street 17A, Vilnius

Contact the seller

MBA Modified Bitumen Plant / Usines de Bitume Modifié / مصنع البيتومين المعدل

Asphalt plant

New

Turkey, Asem Sanayi Sitesi Susuz Mahallesi Küme Evler No:379/10 Yenimahalle / Ankara

Published: 9d

Ask for price

New

Turkey, Asem Sanayi Sitesi Susuz Mahallesi Küme Evler No:379/10 Yenimahalle / Ankara

Contact the seller

See all photos (5)

All Brand Asphalt Plant Spare Part / Pièces de rechange centrale d'enrobage / قطع غيار لمحطة الأسفلت

Asphalt plant

New

Turkey, Asem Sanayi Sitesi Susuz Mahallesi Küme Evler No:379/10 Yenimahalle / Ankara

Published: 9d

Ask for price

New

Turkey, Asem Sanayi Sitesi Susuz Mahallesi Küme Evler No:379/10 Yenimahalle / Ankara

Contact the seller

See all photos (6)

MBA Bitumen Melting Machine / Usine de Fusion de Bitume / آلة صهر البيتومين

Asphalt plant

New

Turkey, Asem Sanayi Sitesi Susuz Mahallesi Küme Evler No:379/10 Yenimahalle / Ankara

Published: 9d

Ask for price

New

Turkey, Asem Sanayi Sitesi Susuz Mahallesi Küme Evler No:379/10 Yenimahalle / Ankara

Contact the seller

See all photos (12)

TICAB New Mini-asphalt plant, Asphalt Recycler, Manufacturer, 2.0 t per hour

Asphalt plant

New2025Net weight: 1500 kg10 hp

Poland, 35-322 , ul.Spichlerzowa 38C Rzeszow, Poland

Published: 16d

Ask for price

New2025Net weight: 1500 kg10 hp

Poland, 35-322 , ul.Spichlerzowa 38C Rzeszow, Poland

Contact the seller

2006 WIRTGEN KMA200

Asphalt plant

2006350 h

China, TianE'HuPan, Dongliu Rd. Hefei, Anhui

Published: 1mo 20d

Ask for price

2006350 h

China, TianE'HuPan, Dongliu Rd. Hefei, Anhui

Contact the seller

See all photos (5)

Constmach Mobile Asphaltanlagen vom Batch-Typ

Asphalt plant

New2025

Germany, Bavyera, Almanya

Published: 2mo 8d

Ask for price

New2025

Germany, Bavyera, Almanya

Contact the seller

See all photos (5)

Constmach Mobile Asphaltanlage

Asphalt plant

New2025

Germany, Bavyera, Almanya

Published: 2mo 8d

Ask for price

New2025

Germany, Bavyera, Almanya

Contact the seller

See all photos (11)

Constmach Stationäre Asphaltanlage wird auf Lager geliefert.

Asphalt plant

New2025

Germany, Bavyera, Almanya

Published: 2mo 8d

Ask for price

New2025

Germany, Bavyera, Almanya

Contact the seller

See all photos (9)

Constmach Feste Asphaltanlagen vom Batch-Typ

Asphalt plant

New2025

Germany, Bavyera, Almanya

Published: 2mo 8d

Ask for price

New2025

Germany, Bavyera, Almanya

Contact the seller

See all photos (9)

Constmach Mobile Batch Type Asphalt Plants

Asphalt plant

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Published: 2mo 8d

Ask for price

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Contact the seller

See all photos (10)

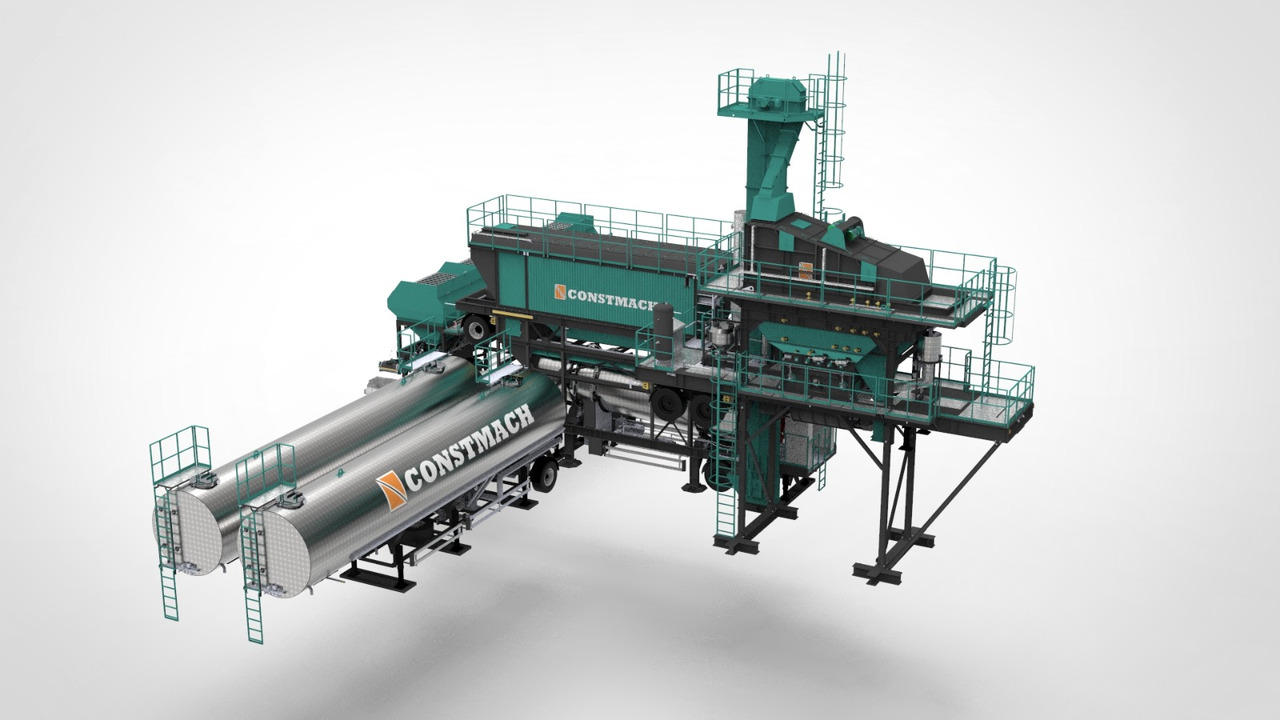

Constmach Mobile Asphalt Plant

Asphalt plant

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Published: 2mo 8d

Ask for price

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Contact the seller

See all photos (11)

Constmach Stationary Asphalt Plant Delivered in Stock 2 Year Warranty

Asphalt plant

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Published: 2mo 8d

Ask for price

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Contact the seller

See all photos (20)

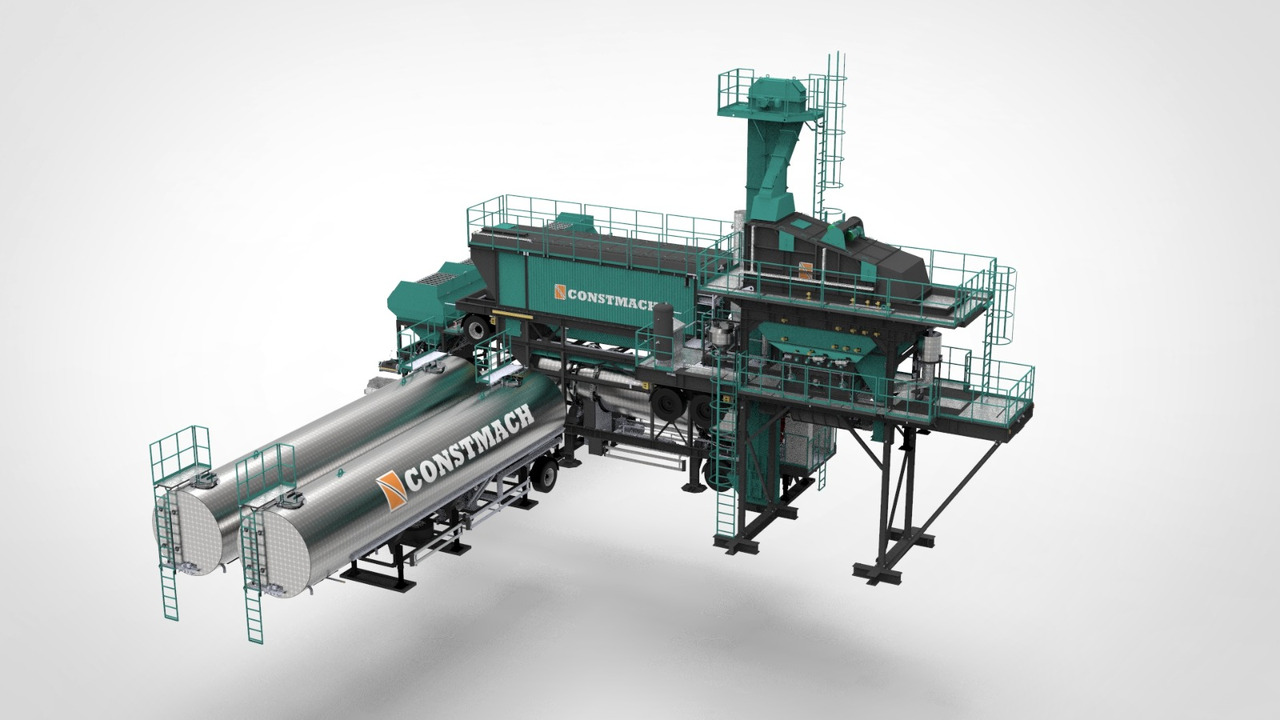

Constmach Stationary Batch Type Asphalt Plants

Asphalt plant

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Published: 2mo 8d

Ask for price

New2025

Turkey, Halilbeyli Bayosb Anadolu Cad. No:1 Bağyurdu Organize Sanayi Bölgesi, Kemalpaşa/İzmir

Contact the seller

See all photos (10)

Constmach Centrales D'asphalte Mobiles de Type Batch

Asphalt plant

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Published: 2mo 11d

Ask for price

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Contact the seller

See all photos (10)

Constmach Centrale D'asphalte Mobile

Asphalt plant

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Published: 2mo 11d

Ask for price

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Contact the seller

See all photos (19)

Constmach Centrale D'asphalte Stationnaire Livrée en Stock Garantie 2 ans

Asphalt plant

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Published: 2mo 11d

Ask for price

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Contact the seller

See all photos (21)

Constmach Centrales D'asphalte Fixes de Type Batch

Asphalt plant

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Published: 2mo 11d

Ask for price

New2025

France, 2 Rue des Francs Bourgeois, 75003 Paris, Fransa

Contact the seller

See all photos (47)

Ermont TSMR17XL

Asphalt plant

2001

France, 20 RUE DU MESNIL 02200 ACY France

Published: 4mo 7d

Ask for price

2001

France, 20 RUE DU MESNIL 02200 ACY France

Contact the seller

Page 1 of 2

T1 new listing page - Asphalt plants leasing