Workshop equipment

Werkzeugschrank

Werkzeugschrank DECKEL

Werkbank HERBA

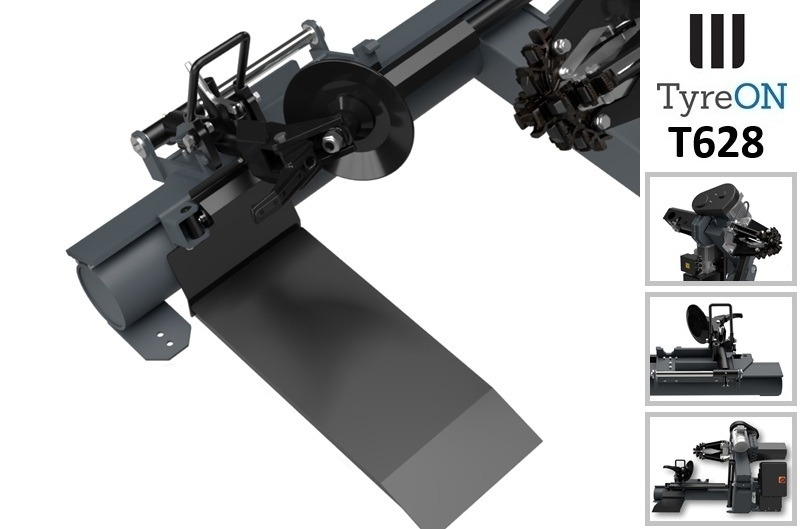

T628 truck tyre changer 28 inches - Tyrewidth uo to 85 cm - 5 clamping positions on jaw - 2 mounting speeds - Power 3,2 kW+2,2 kW

4 250EUR

- ≈ 4 989 USD

- ≈ 3 704 GBP

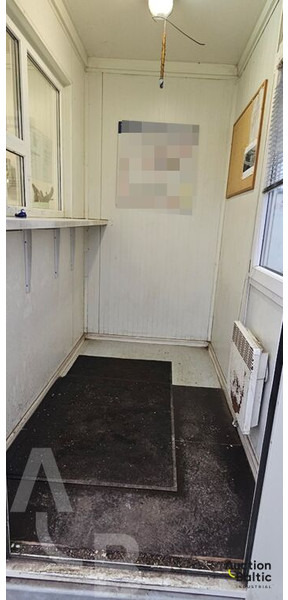

Container office container

8 000EUR

Price excl. VAT

- ≈ 9 392 USD

- ≈ 6 972 GBP

Construction container office container

400EUR

Price excl. VAT

- ≈ 469 USD

- ≈ 348 GBP

Office container office cabin container

5 200EUR

Price excl. VAT

- ≈ 6 105 USD

- ≈ 4 532 GBP

Karcher Professional Puzzi 10/1 Carpet Cleaner

Honeywell CL30XC 240 Volt Evaporative Air Cooler

Battery Chargers, Spring Compression Set, Tyre Inflator

Unused Box of Chainsaw Chain (3 of)

Karcher Professional Puzzi 10/1 Carpet Cleaner

Nightsearcher 110 Volt Double LED Tripod Work Light (2 of)

Unused Huttemberg Tool Cart

Unused Daewoo 100Litre 230 Volt Wheeled Sprayer

Unused Daewoo DAMS16K

Honeywell CL30XC 240 Volt Evaporative Air Cooler

Single 110 Volt LED Tripod Work Light (2 of)

Karcher Professional Puzzi 10/1 Carpet Cleaner

Cable Reel Stands (2 of)

Workshop equipment refers to an extensive range of machinery and tools used across different industries. These include automotive, construction, manufacturing, and more. The right kind of workshop equipment enhances efficiency, safety, and productivity, making it an essential investment for businesses.

Types

The broad category of workshop equipment spans from smaller tools like hammers, wrenches, and screwdrivers to larger machinery like lathes, milling machines, and hydraulic presses. Specific categories include:

- Garage Workshop Equipment: Tools and machinery used for automotive repairs and maintenance, including tire changers and lifts.

- Auto Workshop Equipment: Equipment used in automotive repair shops, such as diagnostic machines, engine hoists, and welding equipment.

- Industrial Workshop Machinery: Heavy-duty machinery used for manufacturing and metalworking, including CNC machines, lathes, and presses.

The type of equipment needed depends on the industry and specific tasks.

Key Technical Specifications

When selecting workshop equipment, consider the power source (electric, hydraulic, pneumatic), capacity, speed, size, and weight. For industrial workshop equipment, also consider the production rate and compatibility with existing machinery.

Popular Brands and Models

Prominent brands in the workshop equipment market include:

- Husqvarna Known for its high-quality power tools and workshop machinery, offering a wide range of products for various applications.

- Makita: A leading brand in power tools, Makita is known for its durable and reliable equipment suitable for both professionals and hobbyists.

- Hitachi: Offers a variety of industrial tools and equipment, known for its performance and innovative designs.

- DeWalt: Well-regarded for its robust and efficient tools, particularly for heavy-duty and industrial use.

For automotive workshop equipment, brands like BendPak and Dannmar are highly regarded for their reliable vehicle lifts and workshop machinery.

Prices and Availability

The price of workshop equipment varies greatly depending on whether you're buying new or used equipment. New equipment typically comes with warranties and the latest technology, but it can be more expensive. For example, a new Bosch power tool set may cost around €500 to €1,500, while a new DeWalt cordless drill can range from €200 to €700 depending on features.

Used equipment can be more cost-effective, making it a popular option for businesses on a budget. A used Makita drill might be priced between €100 to €400, depending on its age and condition.

Regional trends can also influence equipment availability and price, with some areas having higher demand or more limited supply. For example, industrial workshop machinery might be priced higher in regions with a strong manufacturing presence.

Buy Workshop Equipment on Truck1

Purchasing workshop equipment becomes easier with Truck1. This platform offers a wide range of equipment from trusted sellers, providing you with the flexibility to compare prices and specifications. If you are unsure what you need, simply click on the link "I'm looking for" to post your requirements.

FAQ

Consider the type of work, the size of the workspace, power requirements, the equipment's capacity, speed, and production rate. Also, consider the brand reputation and after-sales service.

Always follow manufacturer guidelines, wear appropriate personal protective equipment, and ensure the equipment is regularly inspected and maintained. Also, ensure operators are adequately trained.

Regular cleaning, timely oiling, and replacing worn-out parts are crucial. Also, schedule regular inspections and follow manufacturer guidelines for maintenance.