Packaging machinery

Rollenbahn Roller

Delfin Orion 600

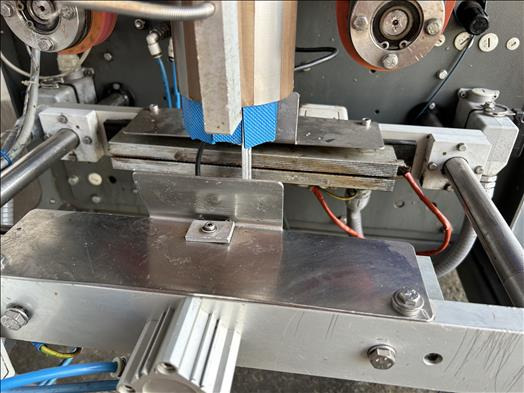

Comarme Gem52 Case taper

Little David LDU/2 case taper

Italdibipack F5025 Shrink tunnel

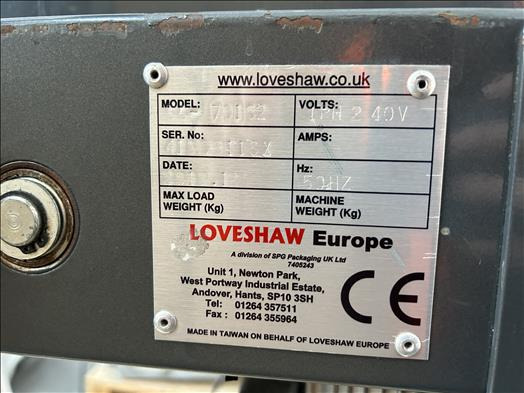

Loveshaw EC701S2 Case taper

Turbo systems Heat sealer pot sealer

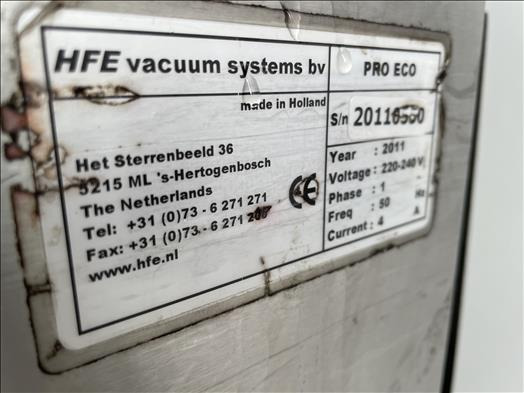

Henkovac Pro eco Vacuum packer

Minipack Torre Modular 50 L-sealing machine

SMI pack FP560 L sealer

NNP KSF450 impulse heat sealer

PAL FP8 Rotary filler

Cpack SS300 sandwich sealing machine

Koenig and Bauer Alphajet Into Inkjet printer

Jacob White TFS Two flap sealer

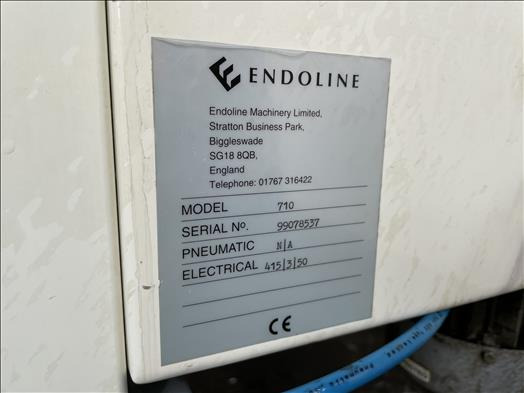

Endoline 710 Case taper

Signode 5FAM Case taper

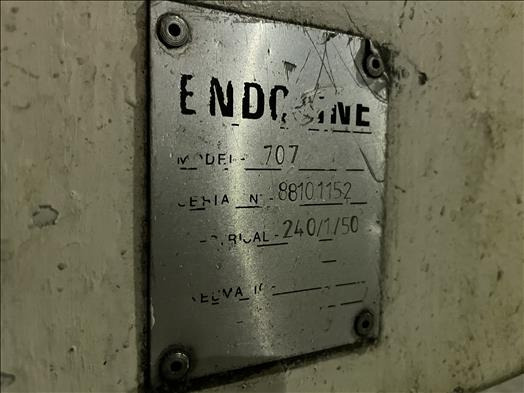

Endoline 707 Case taper

Pentavac Penta2100 VFFS Bagger

PFM Tornado-BBLDSS Flow wrapper

Packaging Machinery for Sale

Packaging machinery refers to a wide range of equipment used in the industrial sector to prepare products for shipping and distribution. These machines automate the process of packing products, ensuring efficiency, uniformity and safety. They find application in various industries, like food and beverage, pharmaceuticals, electronics, and more.

Types of Packaging Machinery

There are several types of packaging machinery available, each designed to perform a specific function. Some common types include:

- Filling Machines: Used for packaging liquids or powders into containers.

- Sealing Machines: Secure packages by sealing them with heat or pressure.

- Wrapping Machines: Cover products with protective film to ensure their safety during transportation.

- Labeling Machines: Add necessary product information, such as barcodes or ingredient lists, to packages.

The type of used packaging machinery that a business needs depends on its specific requirements.

Key Technical Specifications

When selecting packaging equipment, some critical specifications to consider are the machinery's speed (measured in packages per minute), the type and size of packages it can handle, the level of automation, and the machine's power requirements. Always ensure that the machine's specifications align with your operational needs and capabilities.

Popular Brands and Models

Some popular brands in the packaging machinery industry include:

- Bosch: Offers high-speed packaging solutions known for their reliability and precision.

- Krones: Renowned for its beverage packaging systems, providing efficient and automated solutions.

- Tetra Pak: A leading name in food processing and packaging solutions, known for their innovation and sustainability.

Prices and Availability

The price of packaging machinery depends on factors like brand, model, features, and whether the machine is new or used. New machines offer the latest technology, while used ones can be more affordable.

For example, a new Bosch high-speed filling machine may cost between €100,000 and €250,000, while a used Krones packaging line might range from €50,000 to €150,000. A Tetra Pak food processing machine could be priced from €120,000 to €400,000 for new models.

Buy Packaging Machinery on Truck1

If you're looking to buy packaging machinery, consider using the Truck1 platform. With a vast selection of machines for packaging from top brands, Truck1 offers options for both new and used equipment. Their user-friendly platform makes it easy to compare prices and specifications. Start your search today by clicking I'm looking for.

FAQ

Yes, many packaging machines can be adjusted or modified to handle specific tasks. However, the extent of modification depends on the machine's design and capabilities.

You can determine the suitability of a packaging machine by considering factors like its speed, package handling capabilities, automation level, and your production requirements.

Before buying new equipment, you should check its technical specifications and ensure that they align with your existing production and packaging systems. You may also need to consult with the equipment manufacturer or a technical expert.