Crushers from Netherlands

Terex Evoquip Cobra 290 R rotary crusher return compact

235 000EUR

Price excl. VAT

- ≈ 276 992 USD

- ≈ 204 394 GBP

Lindner Urraco 75 D Powerline, U75D

147 000EUR

Price excl. VAT

- ≈ 173 267 USD

- ≈ 127 855 GBP

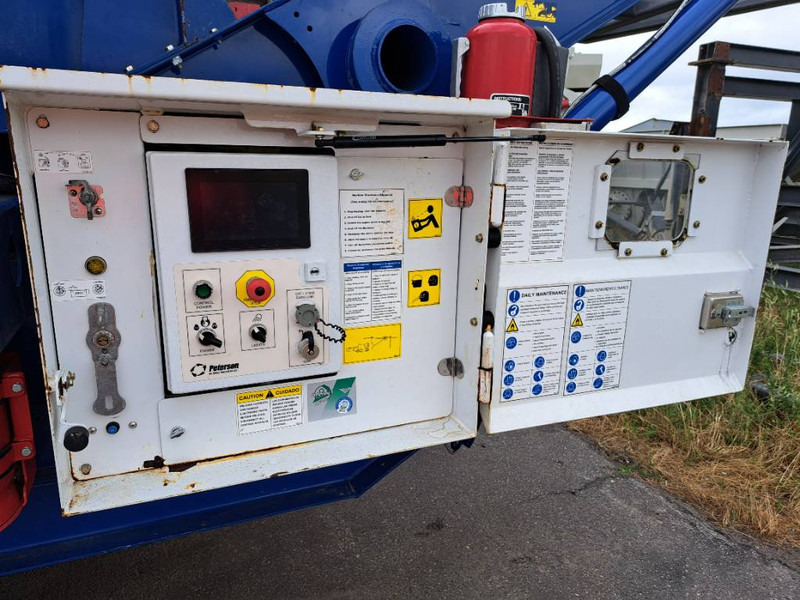

Peterson 1710D

395 000EUR

Price excl. VAT

- ≈ 465 582 USD

- ≈ 343 556 GBP

Lindner Urraco 95DK, U 95 DK, U95DK

Kue-ken 114 (42x27)

Nordberg-Symons 51" Shorthead

Metso GP11FM

Powerscreen 1150 Maxtrak

Kue-ken 106

Kleemann MR 110Z Evo 2

McCloskey J40 V2

174 950EUR

Price excl. VAT

- ≈ 206 211 USD

- ≈ 152 165 GBP

Kleemann MC110Z EVO Jaw Crusher

175 000EUR

Price excl. VAT

- ≈ 206 270 USD

- ≈ 152 208 GBP

Kleemann MC110Z EVO Jaw Crusher

227 000EUR

Price excl. VAT

- ≈ 267 562 USD

- ≈ 197 436 GBP

MAREKO EM90LB-4

Red Rhino 5000 es crusher 15 kw electric vergruizer 2024 CE

21 500EUR

Price excl. VAT

- ≈ 25 341 USD

- ≈ 18 699 GBP

Terex Cobra 290R

279 950EUR

Price excl. VAT

- ≈ 329 974 USD

- ≈ 243 490 GBP

Kleemann Mobirex MRB 102 RA - Prall crusher

Pronar MRW 2.85G (Top condition)

Doppstadt DW3060 - German Machine / Mercedes-Benz Engine

64 500EUR

Price excl. VAT

- ≈ 76 025 USD

- ≈ 56 099 GBP

Kleemann MRB130RH - German Machine / Return Conveyor

145 000EUR

Price excl. VAT

- ≈ 170 910 USD

- ≈ 126 115 GBP

Crushers from Netherlands for sale

Crushers from the Netherlands are known for their high performance, advanced engineering, and reliability. Whether you're looking for a new or used crusher, Truck1 offers a wide range of options from reputable Dutch manufacturers.

Why Crushers Are in High Demand

The Netherlands has a well-established construction and mining sector, and crushers from this country are highly regarded for their reliability and efficiency. Dutch-made crushers are in demand due to the following factors:

- Technological Innovation: Crushers from the Netherlands often feature advanced technology, including energy-efficient systems and automation, improving both productivity and environmental sustainability.

- Quality and Durability: Known for their strong build quality, crushers are designed to handle harsh working environments, ensuring long-term performance and minimal downtime.

- Cost-Effectiveness: Dutch crushers offer a balance of quality and affordability, making them a cost-effective solution for various construction, mining, and recycling applications.

- Strategic Location: The Netherlands' strategic location in Europe provides easy access to both local and international markets, making it a hub for machinery production and export.

Most Popular Crushers

- Metso Lokotrack LT1213S – Known for its fuel efficiency and versatility, this mobile crusher is ideal for crushing medium to hard materials and is highly favored in the recycling industry.

- Sandvik QJ241 – A compact yet powerful crusher that offers high productivity with minimal maintenance, making it a top choice for construction and demolition projects.

- Terex Finlay J-1170 – This jaw crusher is designed for high throughput and can handle a variety of materials, including hard rock, recycling materials, and gravel, offering excellent productivity and reliability.

- Kleemann Mobicat MC 110 Z EVO – A robust mobile crusher that delivers excellent performance in tough environments, this model is widely used in the aggregate and recycling industries.

- Powerscreen Premiertrak 400X – Known for its high capacity and advanced design, this mobile jaw crusher is well-suited for large-scale operations and heavy-duty crushing tasks.

Prices

The typical price range for crushers from the Netherlands can vary significantly, commonly falling between €50,000 and €300,000. These prices are influenced by crucial factors such as the machine's age, condition, brand, and any additional features or specifications. It's crucial to consider these aspects to make an informed purchasing decision.

FAQ

Crushers from the Netherlands are widely used in mining, construction, and recycling industries. They are ideal for breaking down large rocks, concrete, and construction debris into smaller, more manageable materials for further processing or recycling.

Crushers from the Netherlands require regular maintenance to ensure optimal performance. This includes inspecting wear parts such as hammers and liners, checking hydraulic systems, and cleaning air filters. Routine maintenance helps prolong the life of the crusher and ensures it operates at peak efficiency.

Dutch crushers are equipped with advanced technologies like automated control systems, energy-efficient motors, and load monitoring features. These technologies help optimize crushing processes, reduce energy consumption, and improve productivity, making Dutch crushers highly efficient in handling various materials.

Prices for Crushers

| Red Rhino 5000 es crusher 15 kw electric vergruizer 2024 CE | year of manufacture: 2024, hours: 342 h, net weight: 2050 kg | 21 500 EUR |

| Kleemann Mobirex MR 130Z | year of manufacture: 2008, hours: 7800 h, net weight: 54000 kg, power output: 458 hp | 125 000 EUR |

| Kleemann MR130ZS EVO K024 Impact Crusher - Dutch Machine! | year of manufacture: 2012, hours: 18272 h, net weight: 62100 kg | 179 000 EUR |

| Nordberg LT1213 | year of manufacture: 2000 | 81 000 EUR |

| MCCLOSKEY J45 - JAW CRUSHER / CE Certified | year of manufacture: 2016, hours: 5549 h, net weight: 41000 kg | 139 500 EUR |

| Peterson 1710D | year of manufacture: 2020, hours: 500 h | 395 000 EUR |

| Kleemann MC110Z EVO Jaw Crusher | year of manufacture: 2020, hours: 6822 h, net weight: 42600 kg, power output: 337 hp | 227 000 EUR |

| Kleemann MR130Z EVO 2 - German Machine / ModWeigh System | year of manufacture: 2015, hours: 7469 h, net weight: 51500 kg | 209 000 EUR |

| Kleemann MR130Z EVO 2 - German Machine / ModWeigh System | year of manufacture: 2015, hours: 7469 h, net weight: 51500 kg | 209 000 EUR |

| Kleemann MRB130RH - German Machine / Return Conveyor | year of manufacture: 2005, hours: 10581 h, net weight: 62850 kg | 145 000 EUR |